- HOME

- Pipe Jacking

ALWAYS ONE STEP AHEAD

- Model

- Enviliner

- Horizonger

- Prestone

PIPE JACKING to lay pipe underground proceeds in many big cities worldwide.

Places where peoples live require Sewerage Treatment Plants to treat huge waste & Pipe jacking to lay many sizes of pipes to it from buildings & houses.

SANWA PIPE JACKING MACHINE Series contributes those pipes laying underground with minimum disturbance of urban activities as well as with minimum public cost born by taxpayers.

In this brochure, we introduce features,general and mechanical specification.

- Compact design

- Position Sensor in the Pilot Tube leading to efficient steering

- Easy & fast jacking to existing manhole available due to dividable Pilot Tube, Casing and Screw.

- Elastic uPVC, ABS, Ceramic and Hume Jacking Pipe applicable due to unique jacking system.

- Wide range of soil Applicable.

- Waste spoils without chemical material saves cost.

- Unique Pipe withdrawal to correct deviation.

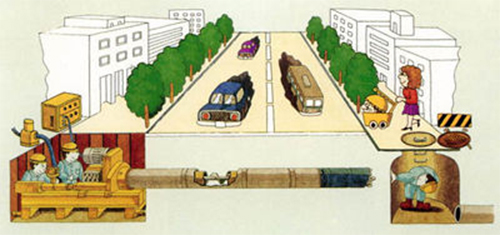

How To Jack

Place the main unit in the launching shaft, and set the pilot tube & back-up pipe to main unit.

Insert the liner casing and auger flight into the laying pipe for preparation before jacking.

Thrust the laying pipe one by one while detecting and steering the thrust direction.

Repeat Item (2), (3) until the pilot tube arrives at the arriving shaft.

After the pilot tube arrives at the arriving shaft, collect the auger head and pilot tube from arriving shaft.

Collect the liner casing and auger flight from the launching shaft.

Emergency extraction

| Auger Head Application | |

|---|---|

| Type | Soil condition |

Standard

|

Ordinary soil Clay, Sandy clay |

Water bearing

|

Water-saturated running sand |

Open

|

Especially Clay and silt |

Heavy duty

|

Very tough clay weathered sand stone qu=up to 200kg/cm2 |

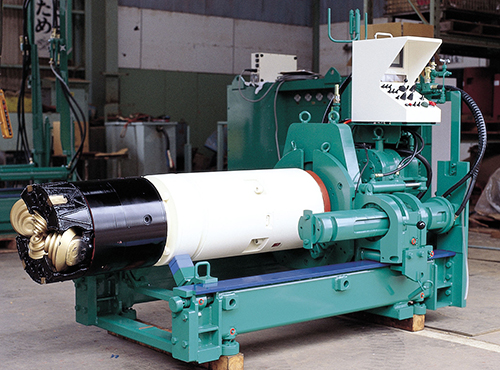

Sanwa Enviliner

Wide Range of Pipe & Diameter

Unique pipe jacking equipment to lay not only PVC pipe but Ceramic Pipe, RCP Pipe, Steel Pipe etc. of which diameter is maximum 580mmφOD. from minimum 200mmφID.

Even their pipes ID. are 150mmφ, it's possible to lay them by means of two (2) stage jacking using Temporary Pipes.

Small Launching Shaft and Arriving Shaft

Sanwa Enviliner SH-456 can be placed in minimum two (2) metersφ Launching shaft to apply congested and restricted area with one (1) meter long pipe. Even 900mmφ existing manhole as an arriving shaft, SH-456 and dividable Pilot Tube achieves jobs to be completed.

Position Sensor System

Sanwa Enviliner SH-456 equips Position Sensor inside of Pilot Tube that will react with Laser Spot discharged from Laser Transit to display their present position, pitching value, rolling value to Monitor in the Operation Panel. Those digital information appeared in the Monitor indicated an operator to start steering action, change of deviation, and to stop steering action.

High Torque & High Thrust Force

Sanwa Enviliner SH-456 has relatively high torque and high thrust force in this class. Maximum 750 kg-m (5410 ft-1b) with stepless rotation speed and max.60ton thrusting force is generated during jacking to apply various kinds of soil condition from hard to soft layer.

Other Line up

As other line up , Sanwa has SEH-508, SEH-616, SH-720TS and SH-1030TS of which applicable dia. Is as per the figure bellow. All of them can be placed in smaller launching shaft compared with conventional model and are driven hydraulically as well as SH-456. Please contact us for further information.

This data. Please swipe lef or right.

| Model | Thrust | StartingPit Circular(Rectangle) |

Applicable Pipe | Nominal Dia x Length (mm) |

|---|---|---|---|---|

| SEH-616 AL |

1600kN (164ton) |

φ2.5m | (1) Vinyl chloride pipe(VU, VP, VM) | φ150-600 x 1000 φ200-600 x 2000 |

| (2) Hume pipe | φ250-500 x 1000 φ250-500 x 2000 |

|||

| (3) Steel pipe and others | φ200-600 x 1000 | |||

| SEH-508 | 800kN (82ton) |

φ2m (4mx2m) |

(1) Vinyl chloride pipe (VU, VP, VM) | φ150-450 x 1000 φ200-450 x 2000 |

| (2) Hume pipe | φ200-400 x 1000 φ200-400 x 2000 φ350-400 x 1000 |

|||

| (3) Steel pipe and others | φ200-400 x 1000 φ200-400 x 2480 |

|||

| SH-456 | 588kN (60ton) |

φ2m (4mx2m) |

(1)Vinyl chloride pipe(VU, VP, VM) | φ150-450 x 1000 φ200-450 x 2000 |

| (2) Hume pipe | φ200-250 x 1000 φ200-250 x 2000 φ300 x 1000 φ300 x 2480 φ350-400 x 1000 |

|||

| (3) Steel pipe and others | ||||

| SH-408 | 784kN (80ton) |

(4.4mx2.4m) | (1) Vinyl chloride pipe (VU, VM) | φ350-450 x 2000 |

| (2) Hume pipe | φ250-350 x 2000 | |||

| SH-355 | 490kN (50ton) |

φ2m (4mx2m) |

(1) Hard vinyl chloride pipe (VU, VP, VM) | φ150-350 x 1000 φ200-350 x 2000 |

| (2) Hume pipe | φ200-250 x 1000 φ200-250 x 2000 |

|||

| (3) Steel pipe and others | ||||

| SH-253 | 294kN (30ton) |

φ1.5m | (1) Hard vinyl chloride pipe (with SUS color) | φ200-300 x 1000 |

Please note that some products may be subject to small changes due to continuous studies into design and performance.

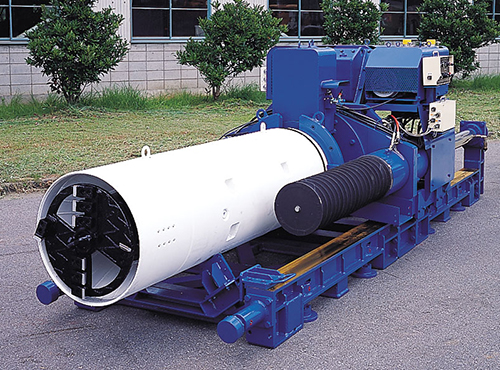

Sanwa Horizonger

The Horizonger is the microtunelling machine that has been developed and manufactured in accordance with our abundant experience of actual job by the contractors and of wide application from vertical and horizontal borings.

The Horizonger Series have been securing outstanding reputation from many both contractors and owners due to minimized deviation and cost saving in microtunelling.

This data. Please swipe lef or right.

| Model | Diameter (mm) | Dimension Main Structure (mm) | Thrust Force | Starting Pit Dimension (mm) |

Soil Conditions | |

|---|---|---|---|---|---|---|

| Hume pipe (I.D) | Steel pipe (O.D) | |||||

| SH-308 | 250~300φ | 350~400A | 4150 x 1200 x 1600 | 80ton | 4800 x 2400 | Normal N Value≦50 Soft-Rock qu≦100 kg/cm2 and Gravel Size.≦50mm |

| SH-408 | 350~450φ | - | 3740 x 1110 x 1425 | 80ton | 4400 x 2400 | |

| SH-716-2 | 250~700φ | 350~800A | 4490 x 1280 x 1500 | 160ton | 5600 x 2800 | |

| SH-720LS-2 | 250~700φ | - | 4630 x 1560 x 1550 | 200ton | 4800 x 2400 | |

| SH-720LS-3 | 250~700φ | - | 4480 x 1550 x 1632 | 200ton | 4800 x 2400 | |

| SH-823 | 350~800φ | 450~900A | 5035 x 1480 x 1510 | 230ton | 6400 x 2800 | |

| SH-1030 | 600~1000φ | 800~1200A | 5250 x 1880 x 2020 | 300ton | 6400 x 3600 | |

Please note that some products may be subject to small changes due to continuous studies into design and performance.

Sanwa Prestone

Although Prestone is a Horizonger basically, it is the procedure which can be constructed by the auger single process system by the earth pressure or balance system especially for water bearing layer.

After the earth and sand excavated by the cutter head are stored in the pilot tube, some soil or sand materials is added to the excavated one to be improved materials, non-water permeability and workability, furthermore the pinch valve can prevent from flow in soil and water in to the pilot tube and the casing, i.e. Earth pressure system, and a special designed disc cutter head is effective to the gravel and rocky soil materials.

This data. Please swipe lef or right.

| Model | Diameter (mm) | Dimension Main Structure (mm) |

Thrust Force (ton) |

Starting Pit Dimensions (mm) |

Soil Conditions | |

|---|---|---|---|---|---|---|

| Hume pipe (I.D) | Steel pipe (O.D) | |||||

| SH-716LSK | 250~700φ | 350~800A | 4490 x 1280 x 1500 | 160 | 5600 x 2800 | Normal, Water Bearing Sandy |

| SH-720LS-2 | 250~700φ | - | 4630 x 1560 x 1550 | 200 | 5600 x 2800 | Normal Water Bearing Sandy Gravel (Max.size ≦1/3 of Pipe dia.) |

| SH-720LS-3 | 250~700φ | - | 4480 x 1550 x 1632 | 200 | 4800 x 2400 | |

| SH-823 | 350~800φ | 450~900 | 5035 x 1480 x 1510 | 230 | 6400 x 2800 | |

| SH-1030LSK | 700~1000φ | 800~1200A | 5250 x 1880 x 2020 | 300 | 6400 x 3600 | |

Please note that some products may be subject to small changes due to continuous studies into design and performance.